If your application calls for engineered resins, the experts at Thogus can help. We’re a full-service injection molding manufacturer that provides comprehensive services from material selection and engineering support to secondary services like pad printing and mechanical assembly. Get in touch with our team today to get started.

Mechanical Strength

Often exhibiting superior mechanical strength and toughness, making them suitable for applications that require durability and impact resistance.

Thermal Stability

Many engineering resins have higher heat resistance, allowing them to withstand elevated temperatures without deformation or degradation.

Chemical Resistance

Engineered resins are formulated to resist exposure to various chemicals, making them ideal for applications associated with harsher environments.

Electrical Properties

Some engineering resins offer excellent electrical insulation properties. As a result, they are commonly used in electronic and electrical components.

Dimensional Stability

Engineered resins typically have low levels of shrinkage during molding, leading to a finished product with enhanced dimensional stability.

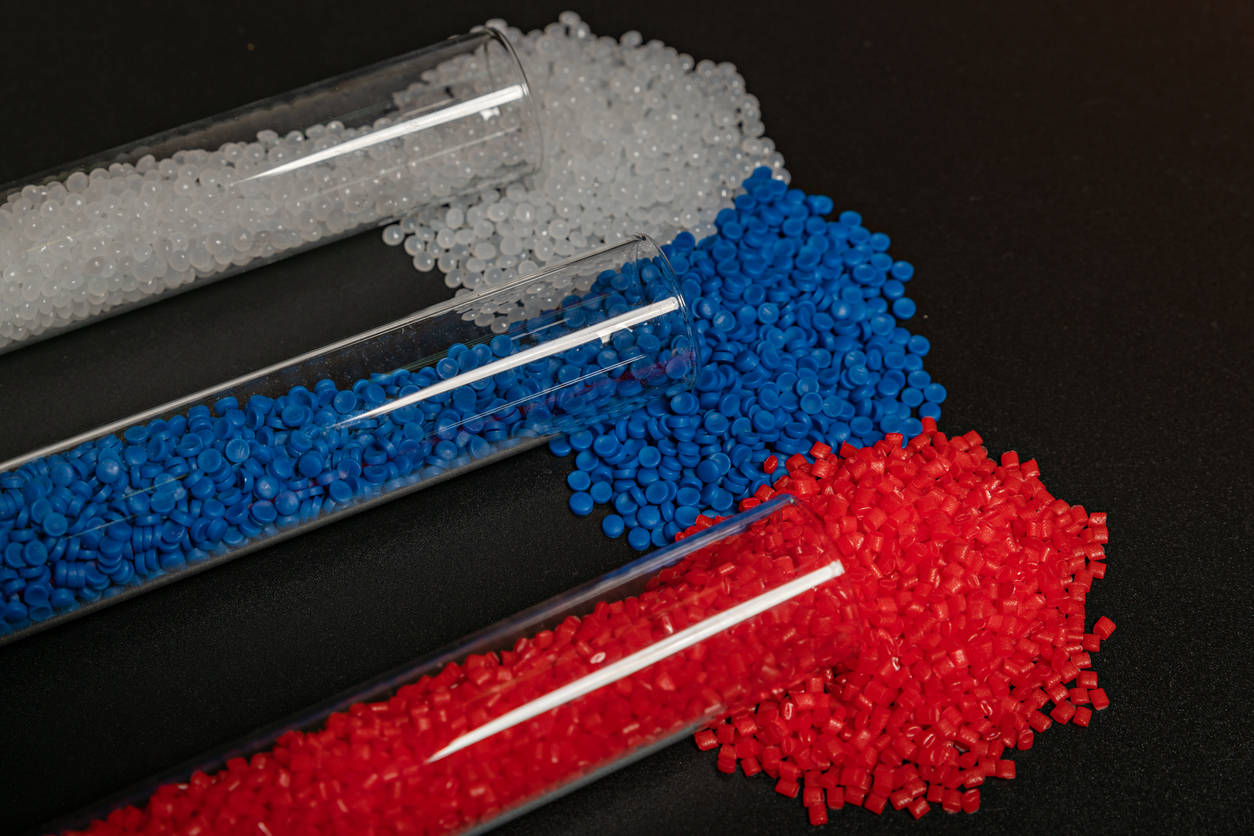

Our Engineered Resins

Some of the engineered resins we work with the most at Thogus include:

-

Nylon (PA6, PA66, and PA12)

-

Polyethylene Terephthalate (PET)

-

Polybutylene Terephthalate (PBT)

-

Polycarbonate (PC)

-

Tritan by Eastman (BPA-free co-polyester)

-

Acetal (POM)

-

Polyether Ether Ketone (PEEK)

-

Polyvinylidene Difluoride (PVDF)

-

Polyether Imide (PEI)

-

Polyphenylene Sulfide (PPS)

Don’t see the material you need? >Reach out to our team to get a full listing of the engineered resins we work with.

Trust Thogus with Your High-Performance Parts

At Thogus we’re an injection molding company that specializes in high-volume manufacturing for customers in a wide range of industries. We work with a variety of standard and specialized materials within the engineered resins category. Reach out today to get started on your next project.