Where Reliability Meets The Road

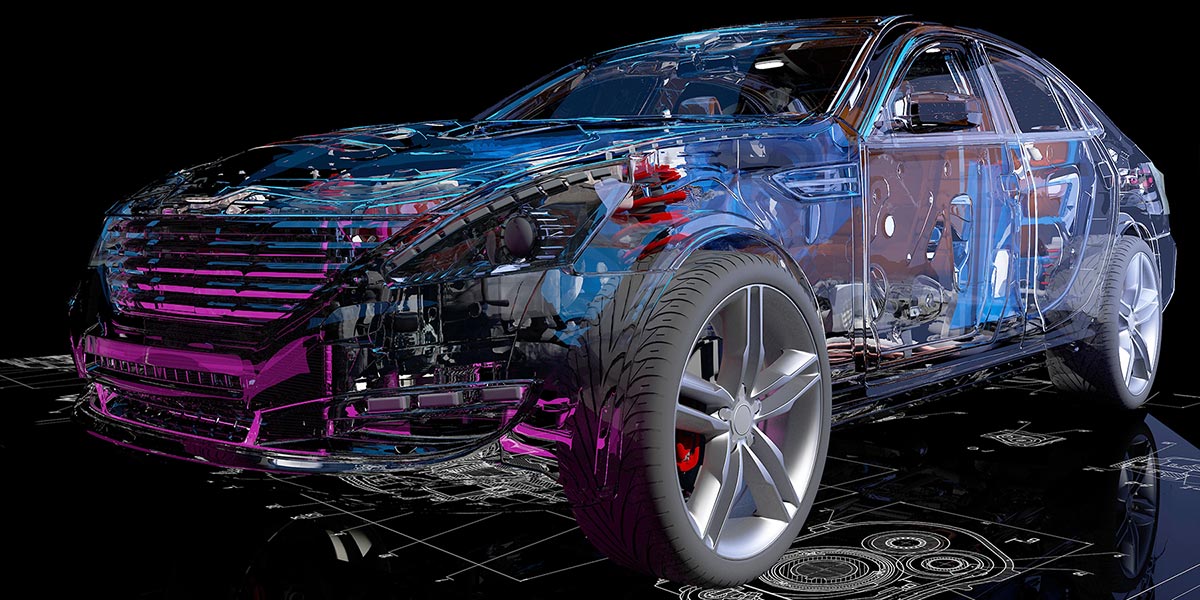

The automotive market depends on components that won't crack or degrade under environmental conditions, vibration and pressure.

The automotive market depends on components that won't crack or degrade under environmental conditions, vibration and pressure.

In the early days of the automotive industry, cars were primarily made of metal, which meant that they were extremely heavy and had poor gas mileage. As the industry advanced, automotive manufacturers began to explore the use of plastic injection molding for vehicle production.

Just like the automotive industry, we evolved our production capabilities as a tool and die company and continuously innovated to help automakers meet the growing demands placed on injection molded plastic parts. Bringing over 70 years of experience to the automotive industry, we frequently supply custom plastic injected molded parts for original equipment manufacturers (OEMS) and suppliers.

In order to meet fuel efficiency standards and reduce carbon emissions, the use of plastics in mainstream and specialty cars and trucks is increasing, with the average car containing 700 pounds of plastics. Our team has extensive experience designing, improving, testing, and manufacturing a variety of automotive plastic injection molded components and electronic subassemblies, including: