Designing Tools for success

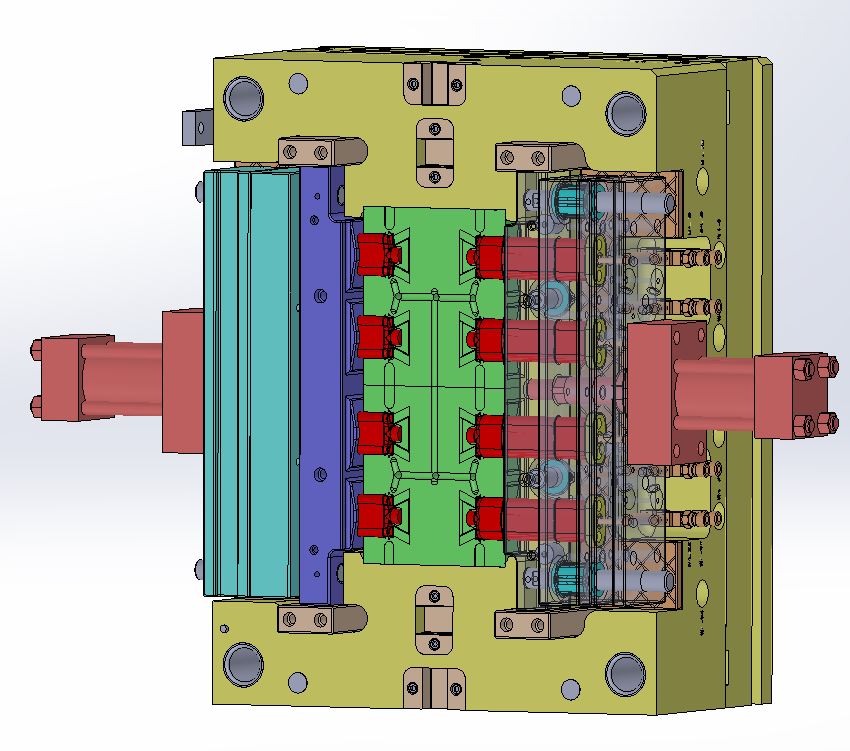

One of the most critical components of plastic injection molding is tooling. If the tool isn’t right, the part’s not right — it’s as simple as that. That’s why properly built tooling is one of the four pillars in our Manufacturing by Design process.

Our dedicated, experienced tooling staff works closely with your engineers to make sure each tool is designed and built right the first time. We understand and recommend how to design tooling to maximize quality and productivity so they’ll satisfy requirements for the entire life of a program.

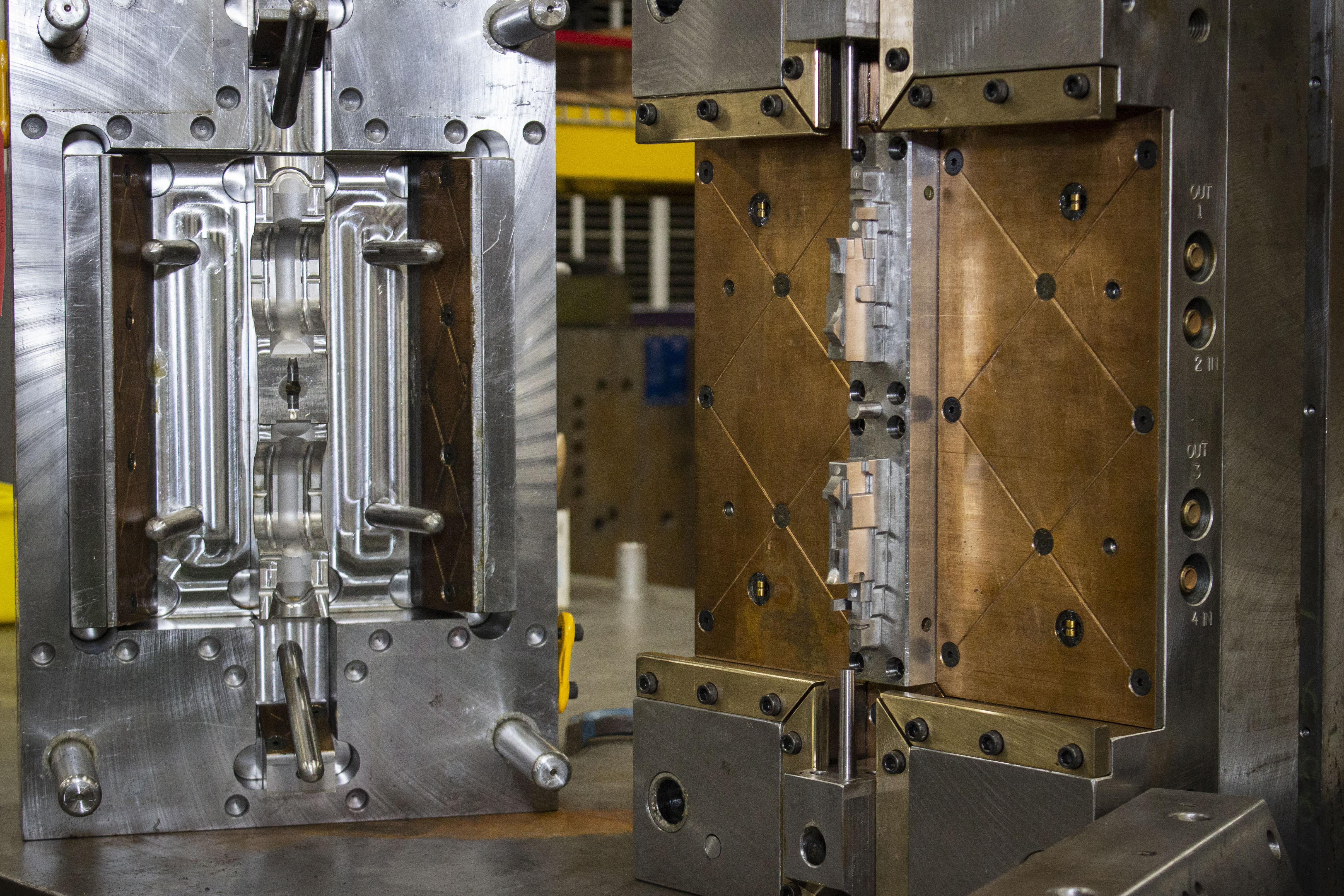

Transfer Tooling Services

It’s a big decision to transfer your tooling and molds to a new plastic injection molding company. If you’re considering transferring your tooling, we’re willing to bet it’s because things haven’t been going smoothly with your current supplier. So why transfer to Thogus? Because we have the expertise, processes, and equipment that can minimize your headaches and have you up and running quickly. If you’re considering making a tooling transfer, contact us to talk through a transition plan that is smooth, efficient, and as hassle-free as possible.

If you're looking for more information, download our free 8-step transfer tooling guide or visit our transfer tooling FAQ page.

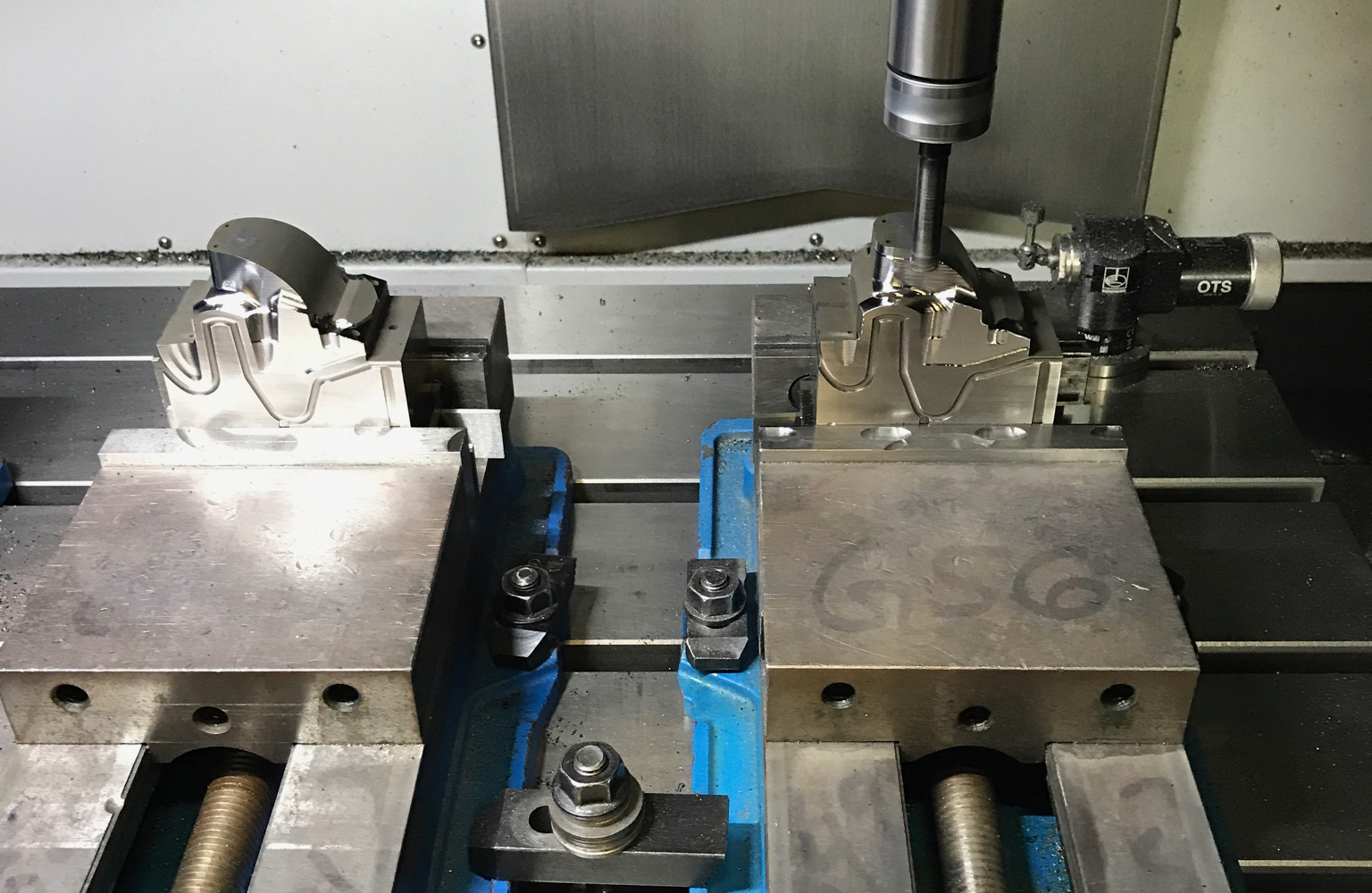

Tooling Maintenance Capabilities

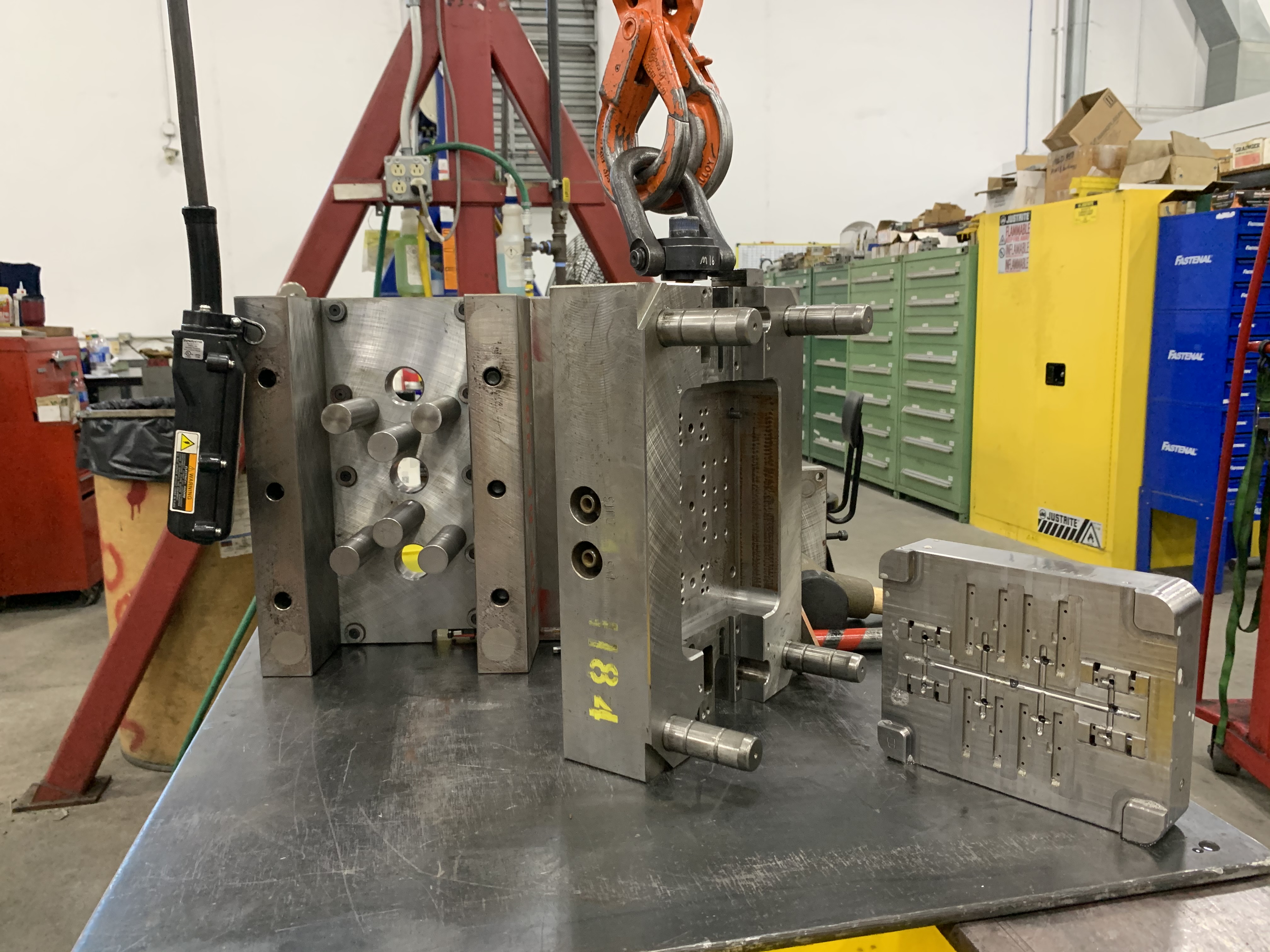

Our dedicated tool room repairs and maintains tooling onsite using high-quality EDM and CNC equipment. To keep downtime at a minimum, we use our ERP system to schedule and manage all tooling preventative maintenance.

Tooling Experts For 60+ Years

Our team has experience running and maintaining all types of injection mold tooling, from single to high cavitation, cold to hot melt delivery systems, two-shot, EDM finish to Class A, and everything in between. Regardless of your tooling requirements, our team is capable of meeting your expectations and recommending improvements when appropriate.