As industries continue to evolve, the need for efficient production processes that provide a distinct edge in product design is crucial. Changes in consumer demands and industry standards require manufacturers to be agile. Often, this means seeking out innovative methods. When it comes to plastic parts production, one such technique is two shot plastic injection molding. Two shot plastic injection molding enables the creation of intricate, multi-material parts in a single manufacturing style. And that’s only the start of the benefits.

What is Two Shot Plastic Injection Molding

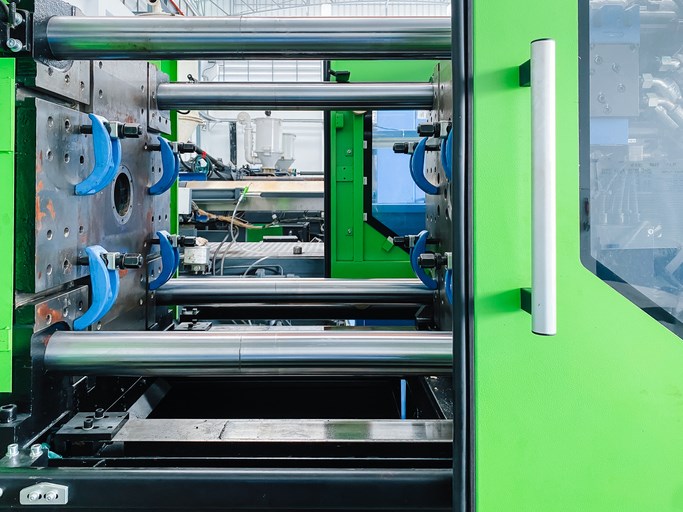

Also called dual-shot injection molding or multi-shot injection molding, two shot injection molding is an advanced plastic molding process. Unlike traditional injection molding, which uses a single material to form a part, two shot molding involves injecting two different materials into a mold to create a finished product.

The Advantages of Two Shot Plastic Injection Molding

Along with the ability to create a multi-material product in a single production run, two shot plastic injection molding offers a variety of benefits, including:

- Enhanced design flexibility—Two shot molding can facilitate the creation of more functional and intricate components.

- Reduced assembly costs—Because the components are integrated during production, the need for secondary assembly processes is minimized, reducing both the time and cost of production.

- Improved product performance—The minimization of assembly processes reduces the risks of defects and improves overall product quality. Additionally, the bond between the two materials enhances the structural integrity of the final product.

Applications of Two-Shot Plastic Injection Molding

It should come as no surprise that two-shot plastic injection molding is an ideal manufacturing method for numerous applications even in some of the most demanding industries.

For instance, in the automotive industry, dual-shot injection molding is pivotal to enhancing the design, functionality, and durability of interior components. One notable example is the creation of soft-touch surfaces on parts like instrument panels, armrests, and door panels. It’s also useful for enhancing the functionality of certain parts of vehicles. Think of the integration of buttons on steering wheels and dashboard controls.

Multi-shot injection molding is also widely used in consumer electronics to address both functional and aesthetic requirements. Ergonomic grips on computer mice, remote controls, and other handheld gadgets are often created with two-shot plastic injection molding. Two-shot molding also enables the creation of products with thinner walls and lighter weight for the sleek, slim products that consumers often prefer.

In the medical and healthcare industries, two-shot injection molding enables the creation of more intricate and hygienic designs. It allows certain devices to be sealed against contamination. Examples include drug delivery devices, surgical instruments, and diagnostic equipment.

Is Two Shot Molding Right For Your Project?

So how do you know if two shot plastic injection molding is right for your product? There are a number of factors to consider and skilled injection molders possess invaluable insights. But in general, if you’re considering two-shot molding, be sure to think about the following:

- Material selection—It’s imperative to be sure that both materials you choose for your product are compatible with the process and with one another. In order to produce a quality product, both materials must bond effectively with one another. However, materials also need to align with the specific requirements of the product. Be sure to consider factors such as strength, flexibility, chemical resistance, and color options.

- Design complexity—While two-shot molding offers significant design flexibility, it’s still important to optimize the design for the manufacturing process. The right injection molding partner will be able to analyze more complex designs to ensure that they can be created without compromising quality.

- Production volume—Finally, two-shot plastic injection molding does come with higher tooling costs compared to more traditional methods. It’s important to be sure that the expected benefits in terms of design flexibility, reduced assembly, and improved product quality justify the initial investment. You should also be sure to discuss scalability with your injection molding partner. Make sure your chosen partner has the capacity to meet your production needs.

Choosing the Right Injection Molding Partner

Having a trusted injection molding partner to carry out the two-shot molding process is essential. In general, you’ll certainly want to find one that has the experience and expertise to deliver two-shot injection molding services in a cost-effective and efficient manner. Having state-of-the-art injection molding equipment and advanced automation is also a major plus, as both can boost production volume without sacrificing quality.

Experience the Difference of Two-Shot Plastic Injection Molding with Thogus

At Thogus, we specialize in mid- to high-volume injection molding services for a number of critical industries. Our capabilities include traditional injection molding, two-shot injection molding, and gas-assisted injection molding. Whatever your project, we have the capacity, the capabilities, and the resources to deliver manufacturing solutions customized to fit your exact needs.

Are you interested in two shot plastic injection molding for your product? Get in touch with our team today to get started.

Experience the Thogus Difference

Connect with us today to discuss your project and to learn more about our capabilities.